Category: Drying equipment

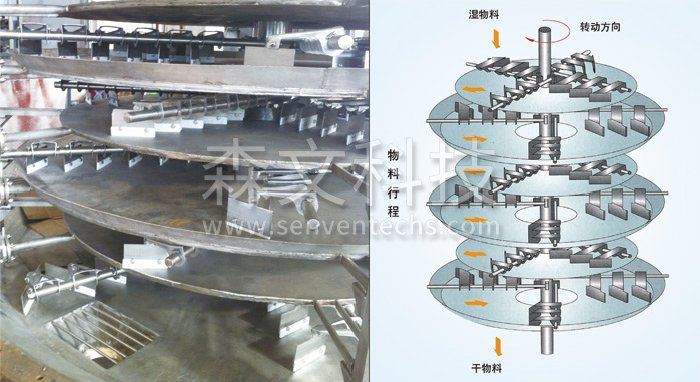

Introduction: Product IntroductionThe disc continuous dryer is an efficient conductive continuous drying equipment. Its unique structure and working principle determine its high thermal efficiency, low energy consumption, small footprint, simple configuration, conv…

+86-15861151117

+86-15861151117

The disc continuous dryer is an efficient conductive continuous drying equipment. Its unique structure and working principle determine its high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. It is widely suitable for drying operations in industries such as chemical, pharmaceutical, pesticide, food, feed, and agricultural by-product processing. Highly praised in various industry usage practices. We currently produce and manufacture three types: atmospheric pressure, sealed, and vacuum, with four types: 1200, 1500, 2200, and 3000. A (carbon steel), B (stainless steel is uniformly distributed in the contact material), and C (based on B, stainless steel is added to the steam pipeline, main shaft, and support, and stainless steel is lined on the cylinder and cover). A series of products with three types of materials and a drying area of 4-180m2, totaling several hundred models, and can provide matching auxiliary equipment to meet the needs of users for drying various materials.

(1) Drying disc

Design pressure: generally 0.4MPa, with an upper limit of up to 1.6MPa.

◎ Service pressure: generally ≤ 0.4MPa, with an upper limit of up to 1.6MPa.

◎ Heating medium: Steam, hot water, heat transfer oil, and drying pan can be heated with hot water at a temperature of 100 ℃, saturated steam or superheated steam of ≤ 0.4MPa can be used at a temperature of 100 ℃ to 150 ℃, heat transfer oil can be used at a temperature of 150 ℃ to 320 ℃, and methods such as electricity, heat transfer oil, and molten salt can be used for heating above 320 ℃.

(2) Material Transfer System

Spindle speed: 1-10 RPM, electromagnetic or variable frequency stepless speed regulation.

◎ Rake arms: There are 2 to 8 rake arms fixed on the main shaft on each layer of drying plate.

◎ Rake blade: It is hinged on the rake arm and can float up and down with the disc surface to maintain contact, with various forms available.

◎ Rolling: For materials that are prone to clumping and need to be crushed, adding rolling at appropriate locations can strengthen heat transfer and drying processes.

(3) The shell comes in three types: atmospheric pressure, sealed, and vacuum

◎ Atmospheric pressure type: cylindrical or octagonal prism type, with two types of structures: integral and split. The main pipeline for heating medium inlet and outlet can be inside the shell or outside the shell.

◎ Closed type: cylindrical shell, capable of withstanding an internal pressure of 5Kpa. The main pipes for heating medium inlet and outlet can be inside the shell or outside the shell.

Vacuum type: cylindrical shell with a design pressure of 0.1Mpa, and the main pipes for heating medium inlet and outlet are inside the shell.

(4) Air heater

Generally used in situations with high evaporation to enhance drying efficiency.

| specifications | outside diameter mm | height mm | drying area m2 | power Kw |

| 1200/4 | Φ1850 | 2718 | 3.3 | 1 |

| 1200/6 | 3138 | 4.9 | ||

| 1200/8 | 3558 | 6.6 | 1.5 | |

| 1200/10 | 3978 | 8.2 | ||

| 1200/12 | 4398 | 9.9 | 2.2 | |

| 1500/6 | Φ2100 | 3022 | 8.0 | |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | Φ2900 | 3319 | 18.5 | |

| 2200/8 | 3739 | 24.6 | ||

| 2200/10 | 4159 | 30.8 | 4.0 | |

| 2200/12 | 4579 | 36.9 | ||

| 2200/14 | 4999 | 43.1 | 5.5 | |

| 2200/16 | 5419 | 19.3 | ||

| 2200/18 | 5839 | 55.4 | 7.5 | |

| 2200/20 | 6259 | 61.6 | ||

| 2200/22 | 6679 | 67.7 | 11 | |

| 2200/24 | 7099 | 73.9 | ||

| 2200/26 | 7519 | 80.0 |

| specifications | outside diameter mm | height mm | drying area m2 | power Kw |

| 2500/6 | Φ3150 | 3319 | 26.3 | 4 |

| 2500/8 | 3739 | 35 | ||

| 2500/10 | 4159 | 43.8 | 5.5 | |

| 2500/12 | 4579 | 52.5 | ||

| 2500/14 | 4999 | 61.3 | 7.5 | |

| 2500/16 | 5419 | 70 | ||

| 2500/18 | 5839 | 78.8 | 11 | |

| 2500/20 | 6259 | 87.5 | ||

| 2500/22 | 6679 | 96.3 | ||

| 2500/24 | 7099 | 105 | 13 | |

| 2500/26 | 7519 | 113.8 | ||

| 3000/8 | Φ3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 |

Previous: QG, JG, FG series airflow dryers

Factors affecting the drying of drying equipment mainly include the following aspects:first, TemperatureTemperature is on…

Controlling the temperature and humidity of the drying equipment is the key to ensure the stability of the drying process…

Selection of suitable high-speed spray dryer needs to consider a number of aspects, the following are some key factors:Fi…

Hotline: +86-15861151117

Long press to recognize WeChat QR code

SenVen Technology