Category: Drying equipment

Introduction: Working principleThis machine is a novel horizontal intermittent vacuum drying equipment. Wet materials are evaporated through conduction, and a scraper stirrer is equipped to continuously remove the materials on the hot surface. The material is then …

+86-15861151117

+86-15861151117

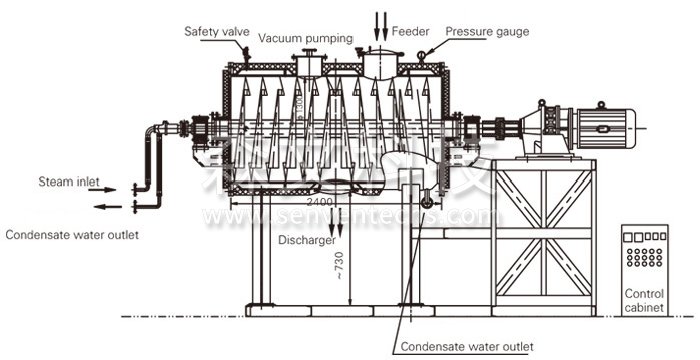

This machine is a novel horizontal intermittent vacuum drying equipment. Wet materials are evaporated through conduction, and a scraper stirrer is equipped to continuously remove the materials on the hot surface. The material is then pushed inside the container to form a circulating flow. After the water evaporates, it is pumped out by a vacuum pump.

| project | model | ||||||

| name | unit | ZPG-500 | ZPG-750 | ZPG-1000 | ZPG-1500 | ZPG-2000 | ZPG-3000 |

| working volume | L | 300 | 450 | 600 | 900 | 1200 | 1800 |

| heating area | m2 | 6 | 7.6 | 9.3 | 12.3 | 14.6 | 19.3 |

| stirring speed | rpm | 6-30 stepless speed regulation | |||||

| power | kw | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 |

| Design pressure of interlayer (hot water) | Mpa | ≤0.3 | |||||

| Vacuum degree inside the cylinder | Mpa | -0.09~0.096 | |||||

Note: The amount of water evaporation is related to the characteristics of the material and the temperature of the thermal inlet and outlet. When the outlet temperature is 90oC, the water evaporation curve is shown in the above figure (for selection reference). As the product is constantly updated, relevant parameters are subject to change without prior notice.

Previous: PLG series disc continuous dryer

Factors affecting the drying of drying equipment mainly include the following aspects:first, TemperatureTemperature is on…

Controlling the temperature and humidity of the drying equipment is the key to ensure the stability of the drying process…

Selection of suitable high-speed spray dryer needs to consider a number of aspects, the following are some key factors:Fi…

Hotline: +86-15861151117

Long press to recognize WeChat QR code

SenVen Technology