Category: Granulation equipment

Introduction: Application areaDrug granulation and coatingGranulation: Tablet granules, granules, capsule granules.Coating: granules, pill protective layer, color preparation, sustained release, film, enteric coating.Food granulation and coatingSugar, coffee, cocoa…

+86-15861151117

+86-15861151117

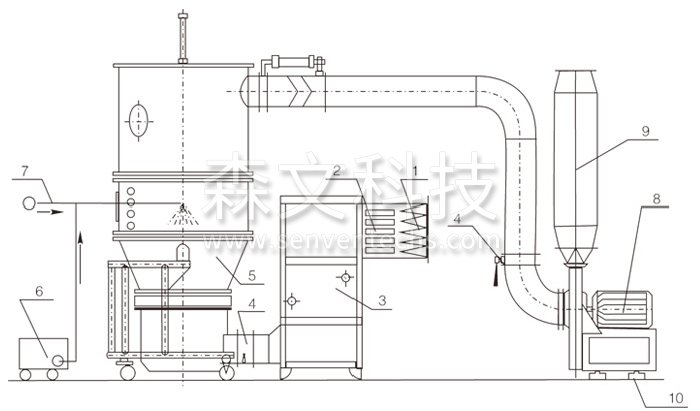

1. Medium efficiency filter 2, sub high efficiency filter 3, heater 4, regulating valve 5, fluidized bed 6, infusion pump 7, compressed air 8, induced draft fan 9, muffler 10, shock absorber

| specifications | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 |

| capacity | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 530 | 660 | 1000 | 1500 |

| Processing capacity | 1.5/4.5 | 4/6 | 10/20 | 15/45 | 25/65 | 40/80 | 60/120 | 80/160 | 90/200 | 100/300 | 150/450 | 300/300 |

| fan power | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 | 30 | 37 |

| Steam consumption | 12 | 23 | 42 | 70 | 99 | 141 | 169 | 211 | 251 | 282 | 366 | 451 |

| Compressed air consumption | 0.3 | 1.3 | 0.3 | 0.4 | 0.4 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.3 | 1.5 |

| noise | (Fan isolation installation) ≤ 75 | |||||||||||

| Overall dimensions |

1.0 ×0.55 ×1.8 |

1.2 ×0.6 ×2.1 |

1.25 ×0.9 ×2.1 |

1.6 ×0.9 ×2.3 |

1.65 ×1.1 ×2.4 |

1.85 ×1.25 ×3 |

1.85 ×1.25 ×3 |

2.2 ×1.65 ×3.1 |

2.27 ×1.72 ×3.1 |

2.34 ×1.9 ×3.5 |

2.8 ×1.9 ×3.8 |

3 ×2.55 ×4.2 |

Note: FG without granulation part

Previous: PGL series spray drying granulator

Factors affecting the drying of drying equipment mainly include the following aspects:first, TemperatureTemperature is on…

Controlling the temperature and humidity of the drying equipment is the key to ensure the stability of the drying process…

Selection of suitable high-speed spray dryer needs to consider a number of aspects, the following are some key factors:Fi…

Hotline: +86-15861151117

Long press to recognize WeChat QR code

SenVen Technology