Category: Drying equipment

Introduction: Product Overview:Roaster is a kind of high-temperature heating treatment equipment for powder or filter cake materials, also known as calcining furnace, according to the different energy sources used, can be divided into coal-fired furnaces, gas furna…

+86-15861151117

+86-15861151117

Roaster is a kind of high-temperature heating treatment equipment for powder or filter cake materials, also known as calcining furnace, according to the different energy sources used, can be divided into coal-fired furnaces, gas furnaces, fuel oil furnaces and electric heating furnaces of four kinds; according to the heating method is divided into two categories of direct and indirect heating; according to the mode of operation is divided into two types of continuous and intermittent operation. Roasters are mainly used for activation, crystal transformation, oxidation, pyrolysis...

Roaster is a kind of high-temperature heating treatment equipment for powder or cake materials, also known as calcining furnace, according to the different energy sources used, can be divided into four kinds of coal-fired furnaces, gas furnaces, fuel oil furnaces and electric heating furnaces; according to the way of heating is divided into two categories of direct and indirect heating; according to the way of operation is divided into two types of continuous operation and batch operation. Roasters are mainly used for activation, crystal transformation, oxidation, pyrolysis, reduction, halogenation, sulfation and other processes, widely used in petrochemical, inorganic chemical, metallurgy, construction and other industries in the production process of special materials.

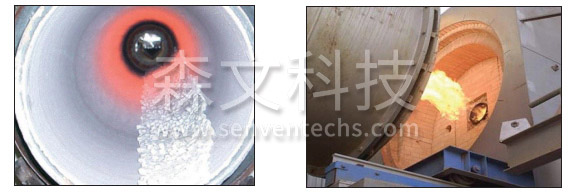

When the indirect heating continuous operation type roaster works, the material enters into the furnace cylinder through the head feeder, and the heating chamber is equipped with electric heating element or fuel burner, and the temperature of the furnace chamber is controlled by the automatic control system through adjusting the electric current of the electric heating element or the flame of the burner, so as to make the material roasted under a certain temperature. The furnace drum is operated horizontally or tilted. The material is roasted in the furnace cylinder while moving forward under the rotation of the furnace cylinder, and the roasted material goes to the next process from the discharge end. The roasting time of the material can be controlled by adjusting the rotating speed of the furnace cylinder or the angle between the cylinder and the level.

Electrically heated roaster uses electricity as energy source. It mainly consists of the main body of the roaster, electric heating system, heat preservation hearth, automatic control system and so on. Our company developed the electric heating roaster in addition to the conventional rotary cylinder roaster, there are vacuum type, positive pressure type, double cone back to the special type of special materials such as special roasters.

Gas-fired roaster mainly consists of roaster body, combustion device, heat preservation hearth, ventilation and smoke exhaust device and automatic control system. Adopting natural gas, water gas and liquefied petroleum gas and other combustible gases as fuel, full combustion, high thermal efficiency, at the same time, the combustion process is easy to control, compared with the solid and liquid fuels on the environment less pollution.

|

Specification mm

|

Rotation speed

|

Typology |

|

DN150~300×5000 |

0.5-5.0 |

Electrically heated rotary cylinder |

|

DN400~500×6000 |

0.5-4.5 |

Electrically heated rotary cylinder |

|

DN600~800×10000 |

0.5-4.0 |

Electric/Gas Rotary Cylinder |

|

DN900~1000×16000 |

0.5-2.5 |

Electric/Gas Rotary Cylinder |

|

DN1100~1300×25000 |

0.5-2.0 |

Electric/Gas Rotary Cylinder |

|

DN1400~1500×25000 |

0.5-2.0 |

Electric/Gas Rotary Cylinder |

|

DN1600~1800×25000 |

0.5-2.0 |

Electric/Gas Rotary Cylinder |

|

DN2000~2300×24000 |

0.5-2.0 |

Electric/Gas Rotary Cylinder |

|

DN1500~2000,1m3~3m3 |

|

Electrically heated double cone rotary |

Note: Due to the large difference in the roasting characteristics of different materials, different roasting process requirements for each material have to do the corresponding structural design, therefore, the data in the above table is only for selection reference.

Factors affecting the drying of drying equipment mainly include the following aspects:first, TemperatureTemperature is on…

Controlling the temperature and humidity of the drying equipment is the key to ensure the stability of the drying process…

Selection of suitable high-speed spray dryer needs to consider a number of aspects, the following are some key factors:Fi…

Hotline: +86-15861151117

Long press to recognize WeChat QR code

SenVen Technology